- Full Atomistic MD

- Coarse Grained MD

- Molecular structure / Affinity / Solubility

- Material Science

[Analysis Example] Construction of amorphous strucuture using reverse-mapping

Efficient creation of relaxation structures for long-chain polymer models

When evaluating polymer properties by simulation, the creation of a bulk model is often the first step in modeling.

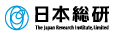

Did you know that the amorphous creation function for creating polymer bulk models in J-OCTA has two options: a normal version and a reverse-mapping version. The Normal version of the functionality starts from a dilute state and creates an equilibrium density bulk state through compression and MD calculations for multiple equilibrations. The reverse-mapping version creates a Kremer-Grest (KG) model for the all-atoms model by specifying the density and characteristic ratio, and then conduct reverse-mapping after the equilibration simulation of the KG model. (Fig.1)

While the normal version is versatile and can be used for any model, it has the issue of long computation time to fully equilibrate the polymer chain. The reverse-mapping version can overcome this issue and reproduce the structural features of the polymer bulk because equilibration is performed by the KG model.

Here, 20, 40, and 60-mers of polyethylene (PE), cis-polybutadiene (PB), and polystyrene (PS) were created with each options. 3 different samples were created for each polymer and degree of polymerization. Then, the structural features of the polymer chains were compared. The force field for the MD calculation was GAFF.

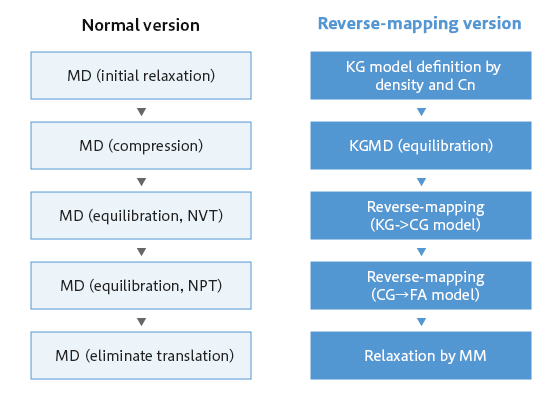

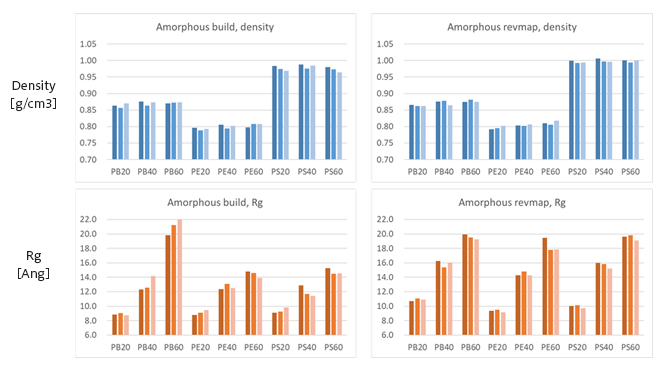

Fig.2 shows the dependence of the density and radius of gyration <Rg>. For density, similar values are obtained by both methods. For <Rg>, differences were observed between the two methods for models with large degrees of polymerization. Fig.3 shows <R2> dependence on the molecular weight of the created bulk models. It is known that the <R2> and <Rg2> of a polymer is proportional to the molecular weight or the degree of polymerization, and this trend was clearly confirmed in the bulk model created using the reverse-mapping. It is confirmed that <R2> of the models created using reverse-mapping agree well with those based on <R2>/M. [1]

Fig.1 Procedures of amorphous model creation for (left) normal version (right) reverse-mapping version.

Fig.1 Procedures of amorphous model creation for (left) normal version (right) reverse-mapping version.

Fig.2 Density and <Rg> of the created polymer model (3 samples for each polymer and degree of polymerization) using (left) normal version (right) reverse-mapping version.

Fig.2 Density and <Rg> of the created polymer model (3 samples for each polymer and degree of polymerization) using (left) normal version (right) reverse-mapping version.

Fig.3 <R2> dependence on the molecular weight of PB, PE and PS models.

Fig.3 <R2> dependence on the molecular weight of PB, PE and PS models.

In the reverse-mapping version, the structure of entangled polymer chains can also be created by performing relaxation calculations using the KG model. [2]

Fig. 4 shows an entangled bulk model of a polycarbonate 25-mer created with this function.

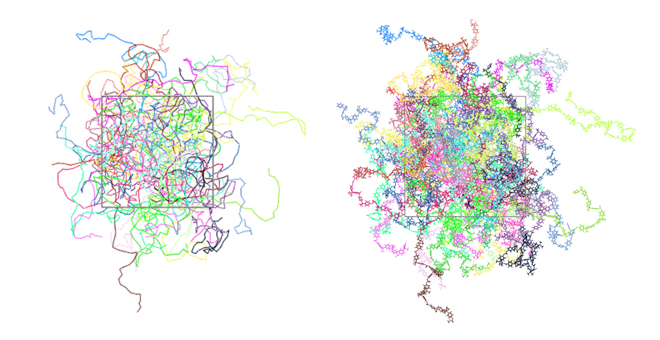

Fig.4 Entangled polycarbonate 25-mer structure created by the reverse map function Left: KG model, Right: Full atomistic model

Fig.4 Entangled polycarbonate 25-mer structure created by the reverse map function Left: KG model, Right: Full atomistic model

- References

- [1] L. J. Fetters, D. J. Lohse, and R. H. Colby, Physical properties of polymers handbook , 445–452 (2006).

- [2] H. Nitta, T. Ozawa and K. Yasuoka, J. Chem. Phys., 159, 194903 (2023).