- Coarse Grained MD

- Mechanical / Viscosity / Viscoelasticity

- Interface / Phase Separation / Particle Dispersion

- Materials Science

Cyclic Deformation of Filled Rubber

courtesy of ![]()

Objective and method

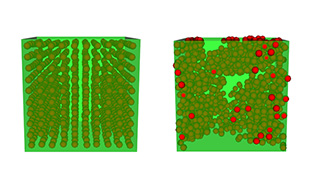

This case example is for evaluating the relationship between the dispersed structure and the macro mechanical property of filled rubber, and for mechanism analysis of the mechanical behavior. Using the Kremer-Grest bead-spring model, dispersed and aggregated structures were created for a coarse-grained molecular dynamics calculation. The calculation was performed with VSOP.

Figure 1. Calculation model, (Left) Dispersed (Right) Aggregated

Figure 1. Calculation model, (Left) Dispersed (Right) Aggregated

Simulation result

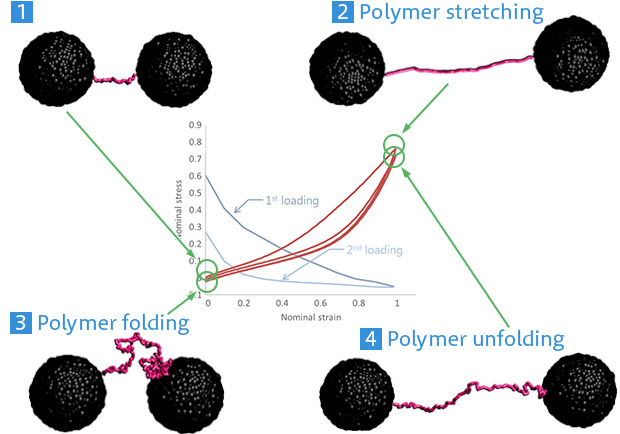

The coarse-grained molecular dynamics simulation successfully reproduced the different dynamic responses due to morphology as those seen in the experiment. Based on the subsequent analysis, the following two points were found; (1) the difference in the dynamic response (Figure 2) is mainly due to the difference in filler stress between the first and second cycles, and, (2) the filler stress possibly depends on the morphology.

The result also revealed that stress softening and hysteresis presented in the dynamic response of the polymer. To verify this finding, the polymer structure between fillers during loading and unloading was examined (Figure 3). According to the verification, the polymer after the first unload is assumed not to have fully-stretched. It shows that the insufficient stretching may have resulted in the softening.

![Figure 2. [Result] Stress-Strain curve](./img/caseA34_img02L.jpg) Figure 2. [Result] Stress-Strain curve

Figure 2. [Result] Stress-Strain curve

Figure 3. Typical polymer conformation between fillers

Figure 3. Typical polymer conformation between fillers