- Coarse Grained MD

- Thermal

- Optical / Electrical / Magnetic

- Interface / Phase Separation / Particle Dispersion

- Other Properties

- Materials Science

Slurry Coating Process

![]()

Courtesy of Toyota Motor Corporation

Objective and method

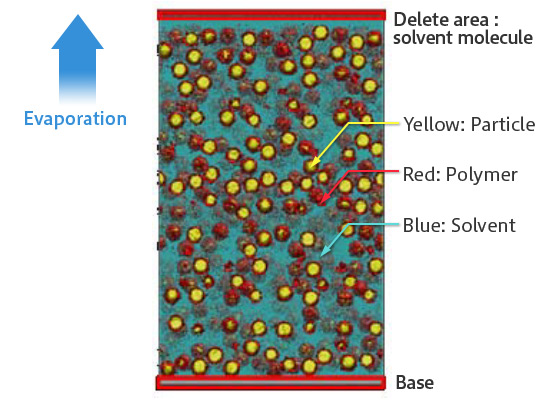

To improve the performance of fuel cells and lithium-ion batteries, Toyota Motor Corporation has conducted a coarse-grained molecular dynamics simulation using a bead-spring model (Kremer-Grest model) for the purpose of clarifying the behavior during the electrode fabrication (slurry coating) process. They used VSOP to calculate the drying process of the slurry. The diffusivity and conductivity of the resulting porous structures were evaluated using MUFFIN (MUltiFarious FIeld simulator for Non-equilibrium system; finite difference method, FDM).

Figure 1. Simulation model of the evaporation of solvent (VSOP)

Figure 1. Simulation model of the evaporation of solvent (VSOP)

Simulation result

Simulated the evaporation process with VSOP and obtained a porous structure after solvent evaporation (Figure 2). From that result, the particle, polymer, and void structures were extracted and their diffusivity and conductivity were simulated (Figure 3). These correspond to the diffusion and conduction of electrons, ions, and gas, respectively, in fuel cells and lithium-ion batteries. The simulation result indicates that the battery performance can be improved by controlling the adsorption property of the polymer and optimizing the porous structure. According to the result described above, this simulation is applicable to the design of meso-structures.

![Figure 2. [Result] Solvent evaporation process (VSOP)](./img/caseA36_img02L.jpg) Figure 2. [Result] Solvent evaporation process (VSOP)

Figure 2. [Result] Solvent evaporation process (VSOP)

![Figure 3. [Result] Diffusivity and conductivity of porous structure (MUFFIN)](./img/caseA36_img03L.jpg) Figure 3. [Result] Diffusivity and conductivity of porous structure (MUFFIN)

Figure 3. [Result] Diffusivity and conductivity of porous structure (MUFFIN)

Comparison of different polymer volume fractions (left),

Comparison of different polymer adsorption properties(right)

This research used computational resources of the K computer provided by the RIKEN Advanced Institute for Computational Science through the HPCI System Research project (Project ID:hp150029).