- Quantum Chemistry / DFT

- Full Atomistic MD

- Multiscale Analysis

- Mechanical / Viscosity / Viscoelasticity

- Materials Science

Cross-Linking of Epoxy Resin by the Monte Carlo method using activation energy

Creating cross-linked structures and evaluating mechanical properties using VSOP

Purpose and Method

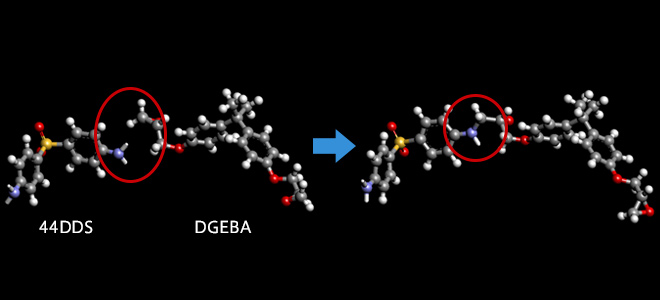

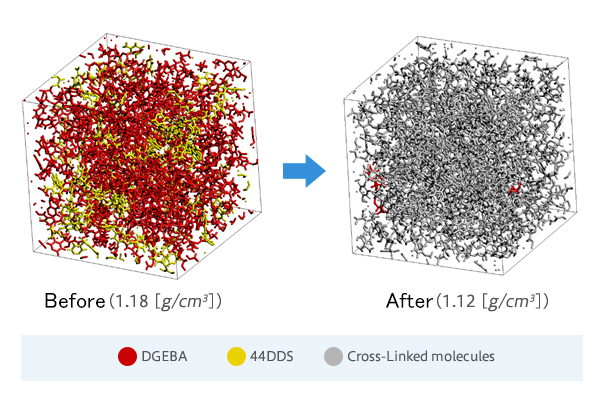

A cross-linked structure of a thermosetting resin (an epoxy resin) was created using J-OCTA (VSOP), and its mechanical properties were determined. The base resin was DGEBA (Diglycidyl ether Bisphenol A) and the curing agent was 44DDS (4’4- Diaminodiphenylsulphone), and they are mixed at a ratio of 2:1.

In J-OCTA, the cross-linking structure is obtained by performing the molecular dynamics (MD) calculation, considering the reaction between specified reactive sites in monomers and cross-linking agents. The reaction takes place according to the specified reaction rate which can be specified based on the activation energy.[1] The algorithm of the reaction calculation is following:

- 1. When the reactive sites approach within the reaction distance.

- 2. The reaction is judged by the Monte Carlo method using activation energy.

- 3. When reaction occurs, reaction heat is generated.

- 4. During the reaction is repeated, the temperature of the system will rise due to the heat of the reaction, and the reaction will be further accelerated.

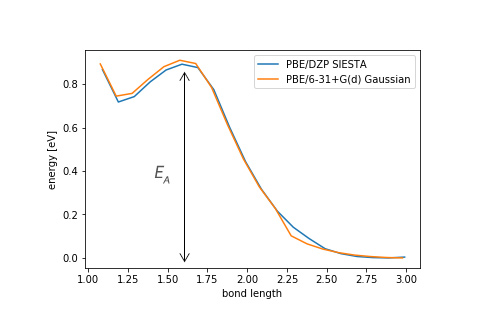

The activation energy can be obtained from ab initio (density functional theory: DFT) calculation, and J-OCTA will establish an easy-use interface with SIESTA.

Figure 1. Process of Cross-Linking reactions (SIESTA)

Figure 1. Process of Cross-Linking reactions (SIESTA)

Figure 2. Activation energy of bond formation between epoxy and amine calculated by DFT (SIESTA)

Figure 2. Activation energy of bond formation between epoxy and amine calculated by DFT (SIESTA)

Figure 3. Process of Cross-Linking reactions (VSOP):

Figure 3. Process of Cross-Linking reactions (VSOP):

The reaction is occurred when the reactive sites approach within the reaction distance

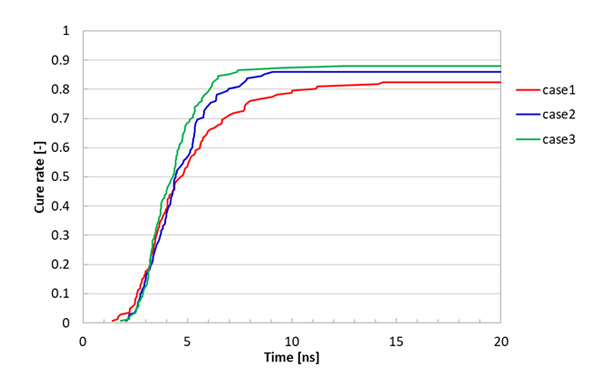

Simulation result

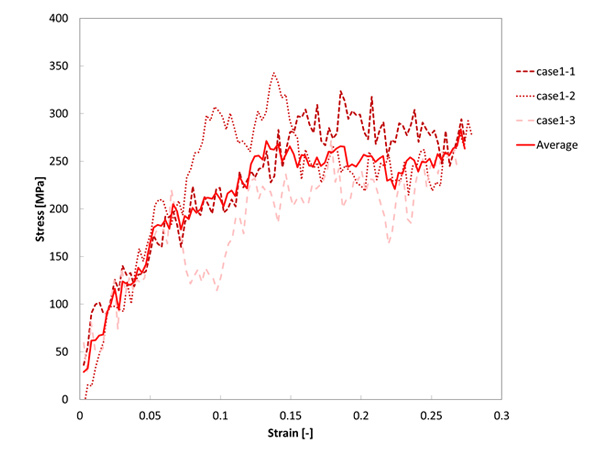

Three cross-linked structures were created from 3 different initial structure. X, Y and Z directional elongation calculations were done for each cross-linked structures.

Finally, all SS curves were averaged and Young’s modulus are evaluated from the averaged curve.

In the reaction calculation with the Monte Carlo method, the degree of cure reached to over 80% and a Young's modulus of 4.15 GPa (experimental value: 3.76 GPa) was obtained.

Figure 4. Molecular structure before and after reaction (VSOP)

Figure 4. Molecular structure before and after reaction (VSOP)

Figure 5. Cure rate (VSOP)

Figure 5. Cure rate (VSOP)

Figure 6. Case1 : Result of elongation calculation (VSOP)

Figure 6. Case1 : Result of elongation calculation (VSOP)

![Figure 7. Case1~3 Result of elongation calculation (VSOP) / Elastic modulus 4.15 GPa (Experiment:3.76 GPa) / Elongation rate 10.22 [m/s] under NPT ensemble / Young’s modulus is evaluated with SS curve fitting of 5% strain](./img/caseA38_img07L.jpg)

Figure 7. Case1~3 Result of elongation calculation (VSOP)

- Elastic modulus 4.15 GPa (Experiment:3.76 GPa)

- Elongation rate 10.22 [m/s] under NPT ensemble

- Young’s modulus is evaluated with SS curve fitting of 5% strain

- Reference

- [1] Tomonaga Okabe, Tomohiro Takehara, Keisuke Inose, Noriyuki Hirano, Masaaki Nishikawa, Takuya Uehara, "Curing reaction of epoxy resin composed of mixed base resin and curing agent: Experiments and molecular simulation", Polymer 54 (2013) 4660-4668.

- [2] V. Sundararaghavan, A. Kumar, International Journal of Plasticity, 47, 111 (2013)