VSOP-PS (Particle Simulation)

Particle-based Fluid, Heat Transfer, and Powder Calculation Engine for Composite Process Design

VSOP-PS is a computational fluid dynamics simulation engine based on the particle method (MPS = Moving Particle Simulation/Semi-Implicit method). The particle method is a simulation method that has strength in its robustness for simulating large deformation. In recent years, the particle method has been applied not only in basic research but also in industrial fields, and many examples can be seen in the automotive, transportation equipment, civil engineering, and construction fields. However, there have not been many applications to materials development on a small scale, such as slurries, which are problems in the battery electrode process, and composite resin materials. Therefore, VSOP-PS, a particle-based mesoscale material process simulation engine, has been developed for developers of battery electrodes, cosmetics, composite resin materials, powder materials, and their manufacturing processes. VSOP-PS analysis covers a spatial scale of tens of nanometers to tens of micrometers and a time scale of micro to milliseconds. Furthermore, VSOP-PS is characterized by its ability to evaluate filler volume fractions, their shapes, and filler-filler interactions.

J-OCTA RVE modeler is required to create VSOP-PS models.

VSOP-PS Case study

-

- Viscosity Evaluation

- lubricating oil, Cosmetics, etc

[Analysis Example] Viscosity of the suspension

-

- Particle dispersion

- Ink, etc.

-

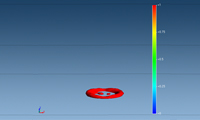

- Droplet evaporation/Coffee ring

- Inkjet printer, etc.

-

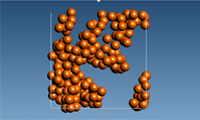

- Powder compression (DEM method)

- Battery electrode, etc.

[Analysis Example] Calculation of pressure and porosity in the forming process (calendaring) of battery electrodes

-

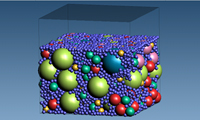

- Thermal conductivity

- Semiconductor sealing and etc.

[Analysis Example] Thermal conductivity calculations for filler resin composites

-

- Impregnation

- CFRP and etc.

[Analysis Example] Resin impregnation process calculation for fiber structure by VSOP-PS